FEA: A tool to manage risk in product innovation

Despite its many advantages, FEA is little known within parts of the design world and even less understood outside the industry. A quick dive into the subject is worthwhile for anyone with an interest in product design.

FEA, What is it?

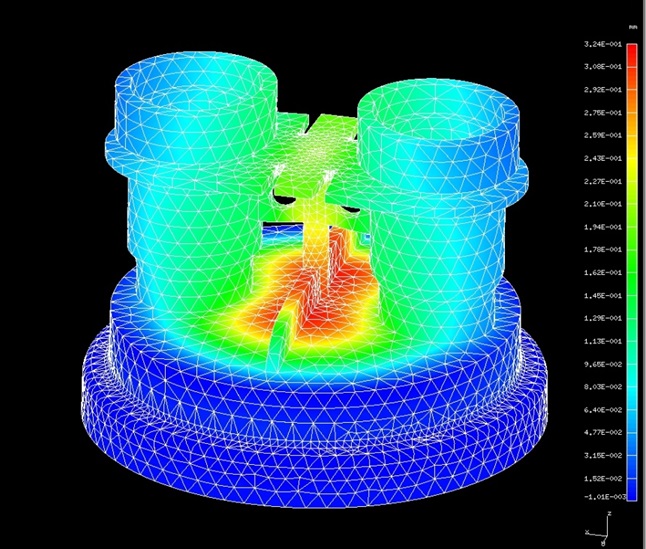

FEA stands for Finite Element Analysis and is a tool commonly used by engineers to simulate and evaluate the key properties and functions of the products they develop. FEA splits complex parts into many simple bricks or tetrahedrals called elements that can be analysed using computerised numerical methods. A model is meshed into elements before applying external conditions. In the case of a structural analysis, these will typically be in the form of supports, loads, displacements (or movements) and heat. The software then calculates how the product responds under these conditions by analysing points in each element and it neighbouring elements until the whole picture is resolved, or in the technical language, the ‘stiffness matrix is converged’. Once the software has finished its calculations, it returns results such as stresses, energies and deformations. These can be interpreted by engineers using animations and coloured contour plots such as shown below.

Physical vs virtual testing

The physical testing of complex products can be an expensive, time-consuming activity and although widely accessible 3D printing significantly shortens prototyping timelines, its use for structural purposes remains limited: The 3D printing materials are not entirely representative of production grades, test equipment and fixtures can be expensive and testing can still take considerable time. It can also be difficult to interrogate the results of physical testing. Which part is failing first? Where and how is it failing and what is happening internally?

This is where FEA can be used as a virtual testing platform to accelerate the design process. Before any prototyping is done, it can model the structural behaviour of complex systems and geometries and lower the development risks of product features and functions. It allows exploration of adventurous ideas to be de-risked and enables potential failures to be detected early in the process so that design changes can be made when they are still inexpensive. In later stages it becomes a powerful optimisation tool and often goes hand-in-hand with prototyping and testing. It can also be used to test worst case scenarios that you probably don’t have physically available.

…Be wary of ‘Garbage In, Garbage Out’!

FEA is a simplification of reality and many factors influence the fidelity of the model and accuracy of the results. These typically include:

- The material data, often only partially available

- The loads applied and assumptions about appropriate safety factor

- The material friction values, which we frequently test to establish

- The mesh density and element type

- The 3D CAD model might differ or be simpler than final products

- The supports and constraints, which have to be correct in all directions and rotations

These sound like many pitfalls to be avoided, and they are. As in computer science, FEA practitioners talk – and warn – about the GIGO syndrome: Garbage In, Garbage Out. In other words, the result is only as good as the data, assumptions and model you use.

Experience, engineering expertise and critical interpretation of the results are the best cure for GIGO. Bench-marking the FEA results is so important and can take the form of a classical calculation or a test of existing parts. It can also be another FEA, performed and validated earlier in the project or created using a different setup. Even when this is done, analysts have to examine results carefully in conjunction with the setup to understand and report any misalignment or simplification from reality.

At PDD we understand the power of FEA as well as its pitfalls. Most importantly we know how to avoid the latter through experience of structural design as well as an intuition of the expected results and the meaning of underlying numbers. Used rigorously, FEA is an incredibly effective tool. It has enabled the rapid development of new solutions that push materials and geometries to their full potential, leading to better user experience, patient safety and cost reductions.

FEA at PDD

PDD has used FEA for over 20 years on several platforms. The applications of analysis have been expanded and refined over the years and today form an integral part of our product development process; from early conceptual stages, through engineering and the verification of design ahead of transfer to manufacture.

PDD engineers and designers use ANSYS Enterprise, considered by many as an industry leading application for structural analysis. We also use Solidworks Flow Simulation for additional fluid and thermal analysis. The technical team is always applying this to new challenges and more recently, free-fall impact simulations have been performed on rugged equipment and medical device projects. This has proven a valuable use of the tool, where we can assess the internal behaviour of a device both during and following an impact. On a recent sterile device project this allowed us to identify potential failure modes, address them in design and reconfirm satisfactory performance in both FEA and physical tests.

Other notable applications of FEA at PDD include:

- Optimising resistance to wind-loading during the development of a rapidly-deployable canopy used for mobile windscreen repair.

- Enabling polymer valves to be used for the innovative new generation of digital showers.

- Analysing weather and flying debris impacts on the new generation of graphical motorway signage systems.

- Ensuring the performance of a spring-loaded, patient-use, drug delivery systems following free-fall impact.

If you need your product innovations to be better performing, more efficient or use less material, then why not challenge us to see what we can do to help you?